In the rapidly evolving landscape of Computer Numerical Control (CNC) machine tools, efficient motor selection is paramount for achieving optimal performance, precision, and productivity. While seemingly straightforward, choosing between a standard motor and a gear motor presents significant implications for CNC applications. This article delves into the key selection points and calculation methods required to differentiate between these motor types, providing a comprehensive guide for CNC engineers and operators. We’ll also touch upon the rising importance of energy efficiency in light of global sustainability initiatives, a topic increasingly relevant to the manufacturing sector. For illustrative purposes, we will refer to MES-Drive, a leading provider of motor solutions.

At its heart, the distinction between a standard motor (often referred to as a synchronous or induction motor) and a gear motor lies in their inherent output characteristics. A standard motor excels at delivering high speeds with relatively lower torque. These are commonly used for tasks like spindle rotation in high-speed machining. However, they often lack the necessary torque for demanding tasks like heavier duty positioning or holding forces.

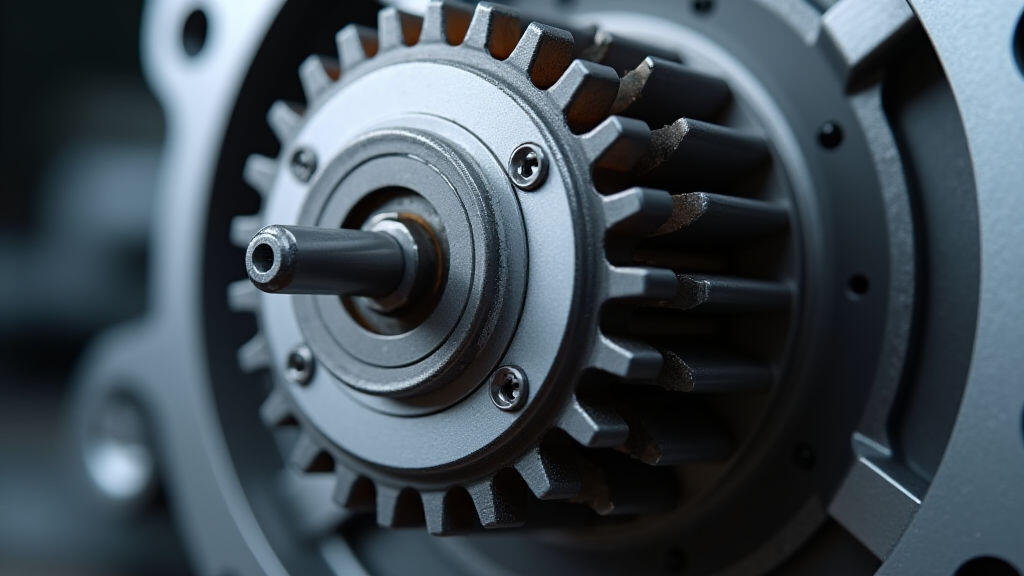

A gear motor, conversely, couples a motor with a gearbox. This gearbox significantly increases torque while reducing speed. This trade-off creates a more versatile solution for a wide range of CNC applications. The reduction in speed is typically accompanied by a corresponding increase in torque, allowing the gear motor to handle heavier loads and exert more force.

Choosing the right motor for a CNC machine tool involves careful consideration of several factors:

Torque Requirements: This is arguably the most critical factor. Analyze the peak torque required for all axes of motion, including acceleration and deceleration phases. Consider the weight of the workpiece, cutting forces, and the required acceleration rates. For example, a milling machine aggressively cutting deep cavities will demand considerably more torque than a lathe performing gentle finishing operations. MES-Drive offers detailed torque calculators to assist in this estimation.

Speed Requirements: Determine the required rotational speed of the driven component. Spindle speed is a primary consideration, but other axes, such as table movement or tool magazine operation, might also have specific speed requirements. The gear ratio in a gear motor will directly impact the output speed.

Accuracy and Precision: The motor's precision and accuracy directly influence the CNC machine's machining accuracy. Look for motors with low backlash and minimal vibration. This is especially crucial for high-precision applications like medical device manufacturing or semiconductor fabrication.

Duty Cycle: Assess the motor's duty cycle – the percentage of time it can operate continuously without overheating. Heavy-duty CNC machines with prolonged machining cycles require motors with high duty cycle ratings. Consider thermal management solutions if necessary.

Size and Weight: Physical constraints within the CNC machine frame are vital. Select motors that fit within the available space and have manageable weight for ease of installation and maintenance.

Efficiency: In today’s eco-conscious environment, energy efficiency is a major concern. Look for motors with high efficiency ratings (e.g., IE3 or IE4) to minimize energy consumption and operational costs. The adoption of renewable energy sources in manufacturing further amplifies the importance of efficient motor solutions.

Control System Compatibility: Ensure the selected motor is compatible with the CNC machine's control system, including voltage, current, and communication protocols.

1. Torque Calculation:

The fundamental equation for torque is:

Torque (T) = Power (P) / Angular Velocity (ω)

Where:

For gear motors, the output torque is the input torque multiplied by the gear ratio:

Output Torque = Input Torque * Gear Ratio

Careful calculation of power requirements is essential. This often involves analyzing the cutting forces, spindle speed, and material removal rate. CNC simulation software can be invaluable in performing these calculations and predicting torque demands under various cutting conditions.

2. Speed Calculation:

Gear motors are used to reduce speed. The relationship between input and output speed is:

Output Speed = Input Speed / Gear Ratio

Therefore, if your CNC machine requires a certain spindle speed and your standard motor doesn't deliver sufficient torque, a gear motor can be the solution. However, remember that reducing speed inherently impacts the overall cycle time of the CNC machine.

3. Backlash Considerations:

Backlash is the amount of play or looseness in the gear system. It affects the accuracy of motion and can lead to positioning errors. During the selection process, critically assess the backlash specifications of the gear motor. Consider using anti-backlash gears if necessary, particularly for precise applications.

MES-Drive offers a comprehensive range of gear motors and standard motors specifically designed for CNC applications. Their expertise lies in providing tailored solutions based on detailed application requirements. MES-Drive's engineers utilize advanced simulation tools to precisely match motor characteristics to specific machining tasks. They provide comprehensive support throughout the selection and integration process, ensuring optimal performance and reliability. They also actively invest in researching and implementing energy-efficient motor technologies, contributing to sustainable manufacturing practices.

Selecting the right motor for a CNC machine tool is a multifaceted decision requiring a thorough understanding of torque, speed, precision, and efficiency. Gear motors provide a valuable solution for overcoming torque limitations while optimizing speed, resulting in enhanced performance and versatility. As CNC technology continues to advance, the demand for high-precision, energy-efficient motor solutions will only increase. With a focus on sustainability and performance, manufacturers are increasingly turning to providers like MES-Drive to optimize their machine tool systems. The integration of AI-powered motor selection tools and predictive maintenance capabilities promises to further streamline the motor selection and management process, ensuring CNC machines operate at peak efficiency and contribute to a more sustainable manufacturing ecosystem.

Leave A Reply

Your email address will not be published. Required fiels are marked